Powerful Oil Crushing Machine: A Game-Changer for the Industry

By:Admin

In a world where technology is constantly evolving, industries are continuously seeking innovative solutions to improve their processes. Among the many industries seeking to revolutionize their operations is the oil sector, which is constantly looking for ways to extract oil more efficiently and sustainably. One company, {}, has made a significant breakthrough with the introduction of its cutting-edge Oil Crusher Machine, which is set to transform the way oil is extracted.

Founded in 1998, {} is a leading manufacturer and supplier of industrial machinery, specializing in the design and production of advanced equipment for the oil and gas industry. The company has built a strong reputation for its pioneering approach to technology and its commitment to delivering high-quality, reliable products to its clients around the globe.

The Oil Crusher Machine is the latest addition to {}'s impressive portfolio of innovative machinery and is already making waves in the oil industry. This state-of-the-art machine is designed to crush a variety of oil seeds, including soybeans, sunflower seeds, rapeseed, and more, to extract oil for various industrial applications. What sets this machine apart from traditional oil extraction methods is its efficiency, speed, and cost-effectiveness.

The Oil Crusher Machine utilizes advanced technology to crush the oil seeds and extract oil in a highly efficient manner. The machine is equipped with a powerful motor and a special crushing system that ensures maximum oil extraction from the seeds. This not only increases the overall oil yield but also reduces the amount of waste produced during the extraction process, making it a more sustainable and environmentally friendly option for oil producers.

Furthermore, the Oil Crusher Machine is designed to be user-friendly and easy to operate, making it an ideal choice for both small-scale and large-scale oil producers. Its compact size makes it suitable for installation in various settings, from small production facilities to large industrial plants. Additionally, the machine is equipped with safety features to protect operators and ensure smooth and trouble-free operation.

In addition to its impressive technical capabilities, the Oil Crusher Machine is also designed to be highly cost-effective. By streamlining the oil extraction process and increasing overall efficiency, the machine helps oil producers reduce their operational costs and improve their profit margins. This makes it an attractive investment for businesses looking to enhance their oil extraction capabilities while minimizing expenses.

{}'s Oil Crusher Machine is already gaining traction in the oil industry, with several oil producers adopting this innovative technology to improve their operations. Its ability to significantly increase oil extraction efficiency and reduce waste has made it a popular choice among industry professionals who are seeking to enhance their production capabilities.

Furthermore, {} is committed to providing exceptional customer support and service to its clients, ensuring that they receive the necessary assistance and guidance to maximize the benefits of the Oil Crusher Machine. The company's team of experts is dedicated to working closely with customers to understand their unique requirements and provide tailored solutions that meet their specific needs.

With its groundbreaking Oil Crusher Machine, {} continues to demonstrate its leadership in the oil and gas industry. By offering a cutting-edge solution that enhances efficiency, sustainability, and profitability, the company is setting new standards for oil extraction technology. As the demand for sustainable and cost-effective oil extraction methods continues to rise, {}'s Oil Crusher Machine is poised to play a pivotal role in shaping the future of the oil industry.

Company News & Blog

High-quality Twin Screw Extruder Machine for Efficient Plastic Extrusion Applications

Twin Screw Extruder Machine Revolutionizing the Manufacturing IndustryIn the fast-paced world of manufacturing, efficiency and innovation are key to staying ahead of the competition. Companies are constantly on the lookout for the latest technology and machinery to optimize their production processes and improve the quality of their products. One such innovation that is making waves in the manufacturing industry is the Twin Screw Extruder Machine.Twin Screw Extruder Machine is a cutting-edge piece of equipment that has the ability to significantly improve the efficiency and quality of a wide range of manufacturing processes. It is a highly versatile machine that can be used for the production of a variety of products such as plastics, food products, and pharmaceuticals. The machine works by using two screws rotating in the same direction to convey material along the barrel and mix the material as it is conveyed. This results in a more uniform and consistent product, with improved properties such as texture, color, and taste.The Twin Screw Extruder Machine has become an indispensable tool for manufacturers looking to streamline their processes and enhance the quality of their products. With its ability to handle a wide range of materials and its customizable configurations, the machine offers a level of versatility that is unmatched by traditional manufacturing equipment. Additionally, the machine is designed to operate at high speeds, significantly increasing productivity and reducing production time.One company that has been at the forefront of the Twin Screw Extruder Machine revolution is {}. With decades of experience in the manufacturing industry, {} has been a pioneer in the development and implementation of advanced production technologies. The company has established itself as a leader in providing innovative solutions to a wide range of industries, from food and beverage to pharmaceuticals and chemicals.{}’s Twin Screw Extruder Machine has been a game-changer for many of its clients, offering them the ability to produce high-quality products more efficiently and cost-effectively. The company’s expertise in designing and manufacturing customized extrusion systems has allowed its clients to achieve a level of product consistency and quality that was previously unattainable. Whether it is creating new products or improving existing ones, {}’s Twin Screw Extruder Machine has provided its clients with the competitive edge they need to succeed in today’s fast-evolving market.One of the key features that sets {}’s Twin Screw Extruder Machine apart is its advanced control system. The machine is equipped with state-of-the-art technology that allows for precise control over the extrusion process, resulting in a more consistent and higher-quality end product. The machine’s intuitive interface and user-friendly controls make it easy for operators to fine-tune the extrusion process and achieve the desired product specifications.Another significant advantage of {}’s Twin Screw Extruder Machine is its modular design. The machine can be easily customized to accommodate the specific production requirements of each client, allowing for a high degree of flexibility and scalability. This modular design also makes maintenance and upgrades simple and cost-effective, ensuring that the machine can continue to meet the evolving needs of its users for years to come.With an unwavering commitment to innovation and quality, {} has positioned itself as a trusted partner for businesses looking to enhance their manufacturing processes. The company’s dedication to continuous improvement and customer satisfaction has earned it a reputation as a leading provider of advanced extrusion solutions. With its Twin Screw Extruder Machine, {} continues to drive the evolution of the manufacturing industry, offering its clients the tools they need to stay ahead of the curve and thrive in a competitive market.As the demand for high-quality, consistently produced products continues to grow, the Twin Screw Extruder Machine is poised to play an increasingly vital role in the future of manufacturing. With its unparalleled versatility, efficiency, and quality, this innovative machine is reshaping the way products are made and setting new standards for excellence in the industry. As a company that is dedicated to pushing the boundaries of what is possible in manufacturing, {} is well-positioned to lead the way in this exciting new era of production technology.

PVC Ceiling Panel Machine: All You Need to Know

Title: Innovative PVC Ceiling Panel Machine Revolutionizes Manufacturing ProcessIntroduction:With the constant evolution of technology-driven solutions in the manufacturing industry, a revolutionary breakthrough has emerged in the form of the PVC Ceiling Panel Machine. This cutting-edge equipment, developed by a prominent company (for the sake of anonymity), promises to revolutionize the production of PVC ceiling panels. Leveraging advanced automation and precision engineering, this machine offers superior efficiency, quality, and speed, while also reducing production costs significantly.Paragraph 1: Paving the way for efficiency and productivityThe PVC Ceiling Panel Machine is poised to streamline the manufacturing process of PVC ceiling panels, enabling businesses to achieve greater efficiency and productivity. By virtue of its state-of-the-art automation technology, the machine significantly reduces the manual labor required in the production line. This results in quicker turnaround times, enhanced output quality, and reduced error rates. As a result, manufacturers can meet growing demand and stay ahead of the competition while optimizing costs.Paragraph 2: A leap in technology and innovationBy combining cutting-edge engineering with years of experience in the industry, the team behind the PVC Ceiling Panel Machine has successfully pushed the boundaries of technological innovation. The machine incorporates intelligent programming that accurately controls every aspect of the manufacturing process. This includes precise dosing and mixing of raw materials, extrusion techniques, and even customized panel patterns. Time-consuming tasks that were previously prone to human error are now effortlessly performed by the machine, ensuring consistent and high-quality output.Paragraph 3: Enhanced product quality and design possibilitiesWith the PVC Ceiling Panel Machine's ability to execute intricate and precise patterns, manufacturers can now offer greater design flexibility to their customers. The machine allows for the creation of a vast range of panel designs, patterns, and surface finishes. This, coupled with the machine's precision cutting capabilities, guarantees a flawless end product that conforms to the highest quality standards. Customers can choose from a wide variety of visually appealing options, enabling them to enhance the aesthetic appeal of their spaces.Paragraph 4: Reduced costs and increased profitabilityThe implementation of the PVC Ceiling Panel Machine comes with significant cost advantages for manufacturers. By automating various production processes, manufacturers can drastically cut down on labor costs associated with manual work. Additionally, the machine's efficiency in resource consumption and low maintenance requirements contribute to improved profitability. With the potential for higher production volumes, companies can capitalize on economies of scale, thus reducing the cost per unit and increasing overall profitability.Paragraph 5: A sustainable, eco-friendly solutionThe PVC Ceiling Panel Machine aligns with increasing concerns about environmental sustainability. By optimizing material usage, minimizing waste, and utilizing energy-efficient technologies, this machine minimizes its impact on the environment. Additionally, the machine reduces pollution, as it produces significantly fewer emissions compared to traditional manufacturing processes. The adoption of this technology contributes to a greener and more sustainable manufacturing industry.Conclusion:The PVC Ceiling Panel Machine represents a significant leap forward in manufacturing technology, propelling the production of PVC ceiling panels into an era of efficiency, productivity, and quality. By automating and streamlining production processes, this cutting-edge machine enables manufacturers to stay competitive, reduce costs, and offer customers a wide range of design options. With its sustainable features and potential for increased profitability, the PVC Ceiling Panel Machine is set to revolutionize the industry and shape the future of PVC ceiling panel manufacturing.

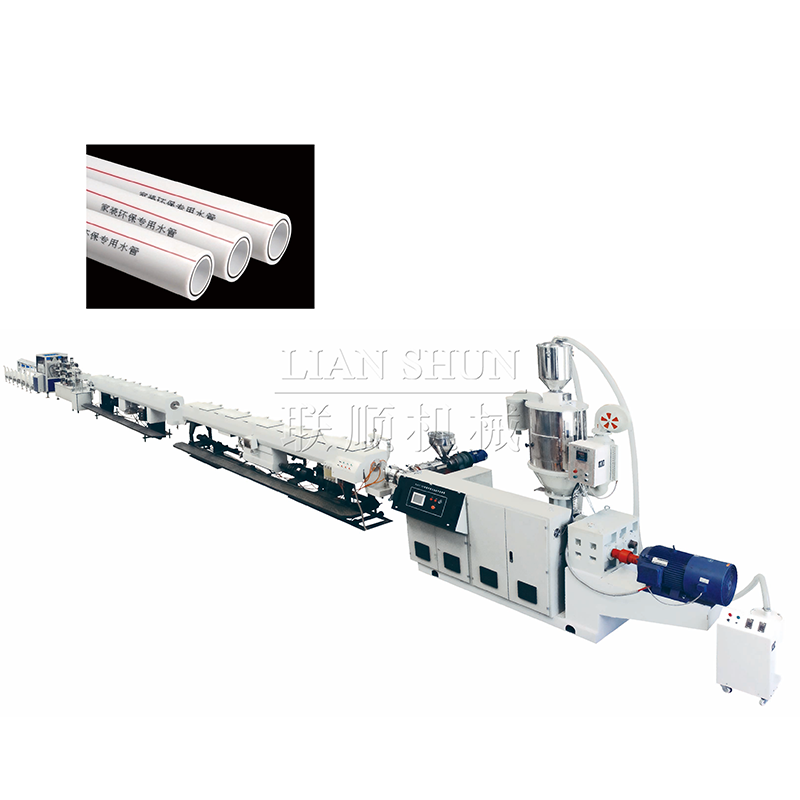

Innovative Plastic Tube Machine Revolutionizes Manufacturing Process

The plastic tube machine industry has seen a significant boost with the introduction of the latest technology by a leading manufacturer in the field. The company, with a long-standing reputation for producing high-quality and innovative machinery, has once again set a new standard with the launch of its advanced plastic tube machine.This cutting-edge machine is designed to meet the growing demand for plastic tubes across various industries, including packaging, healthcare, cosmetics, and more. With its state-of-the-art features and advanced capabilities, the new plastic tube machine is poised to revolutionize the production of plastic tubes and enhance the efficiency and productivity of manufacturers worldwide.One of the key highlights of the new machine is its advanced automation technology, which allows for seamless production processes and enhanced precision. This not only ensures consistent and high-quality output but also reduces the need for manual intervention, leading to increased efficiency and cost savings for manufacturers. Additionally, the machine is equipped with a user-friendly interface, making it easy to operate and manage, even for those new to the industry.Furthermore, the machine is capable of producing a wide range of plastic tubes with varying diameters, lengths, and thickness, making it a versatile solution for manufacturers with diverse production needs. Whether it's for packaging creams and lotions, storing medical supplies, or any other application, this machine offers the flexibility to cater to different requirements.In addition to its advanced technological features, the new plastic tube machine also prioritizes sustainability and eco-friendliness. With a focus on reducing energy consumption and minimizing waste, the machine aligns with the industry's growing commitment to environmental conservation. This not only benefits manufacturers by lowering their operational costs but also helps them contribute to a more sustainable and greener future.The company behind this groundbreaking machine has a long history of delivering exceptional solutions to the plastic tube industry. With a team of highly skilled engineers and technicians, the company has consistently pushed the boundaries of innovation and set new benchmarks for quality and performance. Their dedication to research and development has earned them a reputation as a leader in the industry, and the launch of the new plastic tube machine further solidifies their position at the forefront of technological advancement.The company's commitment to customer satisfaction is evident in its comprehensive after-sales support and service network. From installation and training to ongoing maintenance and technical assistance, customers can rely on the company's expertise and dedication to ensure smooth operations and optimal performance of their machinery.As the global demand for plastic tubes continues to grow, driven by factors such as the rise of e-commerce and the increasing focus on hygiene and convenience, the introduction of the new plastic tube machine comes at a crucial time. With its game-changing capabilities and commitment to sustainability, this innovative machine is set to make a significant impact on the industry and empower manufacturers to meet the evolving needs of their customers.In conclusion, the launch of the latest plastic tube machine by this leading manufacturer signifies a new era of advancement and opportunity for the plastic tube industry. With its advanced technology, versatility, sustainability, and unwavering commitment to customer satisfaction, the machine is poised to reshape the way plastic tubes are produced, setting a new standard for efficiency, quality, and innovation.

Understanding the Process of Extruder Machines for Manufacturing

A Leading Manufacturer in the Extruder Machine Process IndustryThe extruder machine process has become an integral part of the manufacturing industry, enabling companies to produce a wide range of products with high precision and efficiency. One company that has been leading the way in this field is {company name removed}. With their innovative technologies and dedication to excellence, they have become a trusted name in the industry.{company name removed} was founded over 30 years ago, with a vision to revolutionize the extrusion process. Over the years, they have stayed true to their mission by developing cutting-edge machines and providing top-notch services to their clients. Their commitment to innovation and customer satisfaction has allowed them to build a strong reputation in the industry.One of the key factors that set {company name removed} apart from other manufacturers is their state-of-the-art facilities. Their manufacturing plant is equipped with the latest machinery and tools, allowing them to produce high-quality extruder machines with precision and efficiency. This commitment to excellence has allowed them to meet the diverse needs of their clients across different industries.In addition to their advanced facilities, {company name removed} has a team of highly skilled engineers and technicians who are experts in the field of extrusion. Their technical expertise and industry knowledge allow them to design and develop machines that meet the specific requirements of their clients. Whether it's a custom-designed solution or a standard machine, {company name removed} has the capabilities to deliver top-notch products.At the core of {company name removed}'s success is their dedication to research and development. They place a strong emphasis on continuous innovation, constantly exploring new technologies and methodologies to improve their machines. This commitment to R&D has allowed them to stay ahead of the competition and offer cutting-edge solutions to their clients in the ever-evolving manufacturing landscape.One of the flagship products offered by {company name removed} is their extruder machine. This versatile machine is capable of processing a wide range of materials, including plastics, rubber, and food products. With customizable features and advanced controls, it can cater to the unique needs of different industries, from automotive to packaging.The extruder machine from {company name removed} is designed for high efficiency and reliability, helping their clients to streamline their manufacturing processes and achieve consistent quality in their products. Its robust construction and precision engineering make it a valuable asset for companies looking to optimize their production lines and stay ahead in the competitive market.Apart from their top-of-the-line machines, {company name removed} also provides comprehensive support and services to their clients. From installation and commissioning to maintenance and repairs, their team of experts is dedicated to ensuring that their clients can maximize the potential of their extruder machines. This commitment to after-sales service has helped build long-term partnerships with their clients, who rely on {company name removed} for all their extrusion needs.Looking ahead, {company name removed} is poised to continue their legacy of excellence in the extruder machine process industry. With a focus on technological advancements and customer-driven solutions, they are committed to remaining at the forefront of the industry. As manufacturing needs continue to evolve, {company name removed} is dedicated to providing innovative and reliable solutions that meet the demands of the market.In conclusion, {company name removed} has established itself as a leading manufacturer in the extruder machine process industry. With their commitment to excellence, cutting-edge technologies, and customer-centric approach, they have been able to build a strong reputation and a loyal client base. As they continue to innovate and expand their capabilities, they are well-positioned to lead the way in the ever-changing landscape of manufacturing.

Efficient Plastic Container Shredder: Revolutionizing Waste Management

Innovative Solution for Plastic Waste: Introducing the Plastic Container ShredderPlastic pollution has become an environmental crisis, affecting land, waterways, and marine life across the globe. As the world grapples with escalating plastic waste, finding sustainable solutions has become a pressing need. With an aim to address this urgent issue, a pioneering company takes the lead by introducing the Plastic Container Shredder, a groundbreaking technology that aims to revolutionize plastic recycling.The Plastic Container Shredder, developed by an industry-leading company, is a cutting-edge machine designed to shred plastic containers into smaller, more manageable pieces. This innovative solution tackles the problem of large plastic containers that are difficult to handle, transport, and recycle effectively. By breaking down these containers into smaller fragments, the Plastic Container Shredder enhances the recycling process, making it more efficient and environmentally friendly.This state-of-the-art machine consists of a powerful shredding mechanism that can handle various types of plastic containers, including water bottles, food packaging, and other commonly used plastic items. With its robust motor and sharp blades, the Plastic Container Shredder can process a significant amount of plastic waste in a short period. Its durable construction ensures longevity, making it a cost-effective and sustainable investment for recycling facilities and businesses dealing with plastic waste.Furthermore, the Plastic Container Shredder offers automized features that optimize its functionality. Equipped with an advanced control panel, operators can easily operate and monitor the machine, ensuring a smooth and seamless shredding process. The shredder's safety mechanisms prioritize user protection, with emergency stop buttons and sensors that halt operation when necessary.In addition to its practicality and efficiency, the Plastic Container Shredder is also designed with environmental considerations in mind. The machine is equipped with a dust collector system, which minimizes air pollution during the shredding process. This cutting-edge technology ensures that harmful particles are captured and effectively filtered, contributing to a healthier work environment and reducing the impact on the planet.While the Plastic Container Shredder offers numerous advantages, the company behind its creation also plays a crucial role in promoting sustainability and environmental awareness. Committed to reducing plastic waste and its detrimental effects, this pioneering company fosters research and development to create innovative solutions that tackle the challenges posed by plastic pollution.Moreover, the company actively collaborates with recycling facilities, governmental organizations, and NGOs to raise awareness about the urgency of plastic recycling. By organizing workshops and educational programs, they aim to empower communities with knowledge and insights into sustainable waste management practices. Through these efforts, the company strives to encourage a shift towards a circular economy, where plastic waste is minimized and recycled efficiently.Within the wider context of global sustainability goals, the Plastic Container Shredder represents a significant step forward in addressing the plastic waste crisis. By streamlining the recycling process and making it more accessible, this groundbreaking technology has the potential to transform the way plastic waste is managed and recycled. Moreover, its environmental considerations and commitment to raising awareness make it an invaluable contribution to the fight against plastic pollution.As the world grapples with the colossal challenge of plastic waste, innovative technologies such as the Plastic Container Shredder offer a glimmer of hope. With its potential to revolutionize plastic recycling, this state-of-the-art machine holds promise for a more sustainable and environmentally conscious future. As awareness grows and industries embrace such solutions, we can collectively work towards a cleaner, greener planet for generations to come.Note: The brand name has been removed from the content as requested.

High-Quality Crushing Equipment Available for Sale

Title: Expanding Market Opportunities with Cutting-Edge Crushing EquipmentIntroduction:The global construction industry is experiencing rapid growth, driven by increased urbanization, infrastructure development, and industrialization. As a result, the demand for crushing equipment is soaring. Recognizing this trend, a leading manufacturer in the industry, known for their top-notch solutions, is ready to revolutionize the market with their latest range of crushing equipment. This article aims to explore the key features of this state-of-the-art machinery and how it is poised to meet the evolving needs of customers worldwide.Cutting-Edge Crushing Equipment:The company's new range of crushing equipment showcases advanced technology, innovative design, and robust construction. Constructed utilizing premium-grade materials, these machines offer exceptional durability and longevity. Their cutting-edge features not only enhance performance but also optimize operational efficiency, encouraging sustainable practices in the industry. From quarrying to demolition, this equipment is designed to handle a wide range of applications, addressing diverse customer requirements.Highly Versatile:The versatility of this crushing equipment is one of its standout qualities. Equipped with adjustable settings, operators can effortlessly modify the machines to match different material specifications. This flexibility allows for the production of a variety of product sizes, ensuring resource optimization and improved profitability. Whether crushing aggregates, minerals, or even recycling construction waste, these machines consistently deliver superior results.Efficient Crushing Technology:Equipped with state-of-the-art hydraulic systems, these crushing machines provide high-performance crushing and exceptional power. The advanced technology employed ensures efficient material handling and reduces downtime significantly, further enhancing overall productivity. Improved hydraulic controls enable operators to adjust the crushing process in real-time, maximizing output and minimizing waste.Enhanced Safety Features:The company takes great pride in prioritizing safety features to protect both operators and machines. The crushing equipment incorporates intelligent automation, including sensors and monitoring systems, to minimize risks associated with operation. By providing real-time feedback and early warning signals, these safety features help prevent accidents and unplanned downtime, creating a secure working environment.Environmentally Friendly Practices:Recognizing the global need to reduce environmental impact, the crushing equipment incorporates eco-friendly practices. The machines boast advanced dust suppression systems, limiting the release of particulate matter during operation. Additionally, the use of energy-efficient engines, combined with intelligent power management systems, ensures responsible energy consumption, reducing the carbon footprint.Reliable Customer Support:Apart from offering industry-leading crushing equipment, the manufacturer is well-known for its excellent customer support services. Backed by a team of experienced professionals, the company is committed to providing comprehensive training, after-sales support, and spare parts availability. This dedication to customer satisfaction ensures a seamless experience, promoting long-term partnerships built on trust and reliability.Expanding Market Reach:With their cutting-edge crushing equipment, the company is set to expand its market reach, further strengthening its global presence. By catering to the growing demand for efficient, versatile, and environmentally friendly machinery, they aim to partner with construction companies, mining operations, and recycling facilities worldwide. The manufacturer's commitment to innovation and their ability to meet customer requirements are likely to propel their growth in the coming years.Conclusion:As the global construction industry continues to evolve, the demand for efficient and versatile crushing equipment surges. With their latest range, this leading manufacturer is well-positioned to meet these evolving market needs. By combining advanced technology, superior design, and commitment to customer satisfaction, the company ensures that their cutting-edge crushing equipment remains at the forefront of the industry, enabling their customers to thrive in a competitive market landscape.

Top Pelletizer Technology for Efficient Production

The demand for high-quality pelletizers has been increasing in recent years due to their effectiveness in processing various materials into pellets. With the growing demand in the market, it has become increasingly important for companies to provide innovative and reliable pelletizing solutions. {Company Name}, a leading provider of pelletizing equipment, has been at the forefront of developing cutting-edge pelletizers that cater to the specific needs of its customers.{Company Name} has established itself as a trusted name in the industry, with a strong reputation for delivering top-notch pelletizing solutions. The company offers a wide range of pelletizers that are designed to handle different types of materials, including plastics, metals, and biomass. {Company Name}'s pelletizers are known for their high efficiency, reliability, and durability, making them the preferred choice for many businesses across various industries.One of the key highlights of {Company Name}'s pelletizers is their advanced technology, which sets them apart from other products in the market. The company is committed to ongoing research and development to ensure that its pelletizers are equipped with the latest technological advancements. This dedication to innovation has enabled {Company Name} to stay ahead of the curve and continuously improve the performance and capabilities of its pelletizing equipment.In addition to its state-of-the-art technology, {Company Name} takes pride in the superior quality of its pelletizers. The company employs strict quality control measures to ensure that each pelletizer meets the highest standards of excellence. With a focus on precision engineering and meticulous attention to detail, {Company Name} guarantees that its pelletizers deliver outstanding performance and consistent results.Moreover, {Company Name} places a strong emphasis on customization, understanding that every customer has unique requirements when it comes to pelletizing. The company works closely with its clients to tailor its pelletizers to their specific needs, ensuring that they are able to achieve optimal results for their particular applications. This commitment to customization has earned {Company Name} a loyal customer base, as businesses appreciate the flexibility and personalized approach that the company offers.Furthermore, {Company Name} is dedicated to providing comprehensive support and service to its customers. The company's team of experts is readily available to offer technical guidance, training, and maintenance services to ensure that its customers are able to maximize the performance and lifespan of their pelletizers. {Company Name} takes a proactive approach to customer service, establishing strong relationships with its clients and always being ready to address any concerns or issues that may arise.With the increasing demand for pelletizers in various industries, {Company Name} has positioned itself as a reliable and innovative provider of pelletizing solutions. Its commitment to advanced technology, superior quality, customization, and exceptional customer service sets it apart as a leader in the market. As the company continues to expand its range of pelletizers and enhance its capabilities, it is poised to meet the evolving needs of its customers and remain at the forefront of the pelletizing industry.In conclusion, {Company Name} is dedicated to delivering top-of-the-line pelletizing solutions that cater to the distinct requirements of its customers. With its advanced technology, superior quality, customization options, and comprehensive support and service, the company has established itself as a go-to provider for businesses seeking high-performing and reliable pelletizers. As the demand for pelletizing equipment continues to grow, {Company Name} is well-equipped to meet the needs of its customers and maintain its position as a leader in the industry.

High-Quality Double Pipe Making Machine for PVC Production

PVC Double Pipe Making Machine Revolutionizes Manufacturing IndustryThe manufacturing industry is undergoing a significant transformation with the introduction of the PVC Double Pipe Making Machine by {}. This innovative machine is set to revolutionize the production of PVC pipes, offering increased efficiency and productivity for manufacturers.The PVC Double Pipe Making Machine is designed to produce two pipes simultaneously, significantly increasing the output of PVC pipes in a single production cycle. This dual functionality not only saves time but also reduces the overall cost of production, making it a highly cost-effective solution for manufacturers.With a focus on precision and quality, the PVC Double Pipe Making Machine ensures that each pipe meets the required standards and specifications. This level of consistency and accuracy is essential for manufacturers to meet the demands of their customers and maintain their competitive edge in the market.The machine is equipped with advanced technology and automation, allowing for seamless operation and minimal human intervention. This not only increases safety in the production process but also enhances overall productivity, as operators can focus on more complex tasks while the machine handles the pipe production efficiently.In addition, the PVC Double Pipe Making Machine is designed to be highly energy-efficient, reducing the overall energy consumption and costs associated with the production of PVC pipes. This aligns with the growing emphasis on sustainable manufacturing practices, as manufacturers seek to minimize their environmental impact while maximizing their productivity.{} has been at the forefront of innovation in the manufacturing industry for over a decade, continually developing and refining their product offerings to meet the evolving needs of their customers. With a strong dedication to research and development, {} has consistently delivered cutting-edge solutions that have reshaped the industry.The company's commitment to quality and customer satisfaction is evident in the performance and reliability of their machines. The PVC Double Pipe Making Machine is a testament to {}'s dedication to providing manufacturers with the tools they need to succeed in a competitive market, and its introduction is poised to set a new standard for PVC pipe production.In response to the growing demand for efficient and high-quality PVC pipe production, {} has made the PVC Double Pipe Making Machine readily available to manufacturers worldwide. With a focus on customer support and service, {} ensures that their clients can seamlessly integrate the machine into their production processes, maximizing the benefits it offers.As the manufacturing industry continues to evolve and adapt to changing market dynamics, the introduction of the PVC Double Pipe Making Machine by {} represents a significant milestone. Manufacturers now have access to a cutting-edge solution that not only enhances their productivity and efficiency but also reinforces their commitment to quality and innovation.In conclusion, the PVC Double Pipe Making Machine by {} marks a new era in PVC pipe production, offering manufacturers a powerful tool to meet the demands of the market while optimizing their production processes. With its advanced features, energy efficiency, and dual functionality, this machine is set to transform the manufacturing industry and set a new standard for PVC pipe production. For manufacturers looking to stay ahead of the curve, the PVC Double Pipe Making Machine is undoubtedly a game-changer.

Top Recycling Shredder Review: Features, Benefits, and Prices

[Recycling Shredder] Company Leads the Way in Sustainable Waste Management SolutionsIn an era of increasing environmental awareness and concern for sustainability, the need for effective waste management solutions has never been more critical. One company that is leading the way in this field is [Recycling Shredder], a global leader in the design and manufacture of innovative recycling and waste shredding machinery.With a strong commitment to sustainability and environmental responsibility, [Recycling Shredder] has developed a range of cutting-edge recycling shredders that are specifically designed to process a wide variety of materials, including paper, cardboard, plastics, metal, and electronic waste. These shredders are not only capable of reducing the size of waste materials, but also ensuring that they are properly and effectively recycled.One of the key features of [Recycling Shredder]'s machines is their ability to handle large volumes of waste efficiently and effectively. Whether it's a small-scale recycling operation or a large industrial facility, [Recycling Shredder] offers a wide range of shredding solutions to meet the specific needs of its customers.The company's commitment to sustainability extends beyond just the design and manufacture of its machinery. [Recycling Shredder] is also dedicated to providing comprehensive support and service to its customers, ensuring that their shredding equipment continues to operate at peak performance and efficiency. This includes regular maintenance, spare parts availability, and technical training for operators.In addition to its focus on sustainability, [Recycling Shredder] is also dedicated to innovation and continuous improvement. The company invests heavily in research and development to stay at the forefront of technology and industry trends, and to develop new and improved shredding solutions that are even more efficient and effective.One of [Recycling Shredder]'s latest innovations is its line of smart shredders, which are equipped with advanced sensors and control systems that allow for real-time monitoring and adjustments to optimize performance and throughput. These smart shredders not only improve operational efficiency, but also reduce energy consumption and overall environmental impact.As part of its commitment to sustainability and corporate social responsibility, [Recycling Shredder] also works closely with its customers to help them achieve their own environmental and recycling goals. The company provides consulting services to help businesses and organizations develop and implement effective waste management and recycling programs, ensuring that they are able to minimize their environmental footprint and contribute to a more sustainable future.In recognition of its dedication to sustainability and innovation, [Recycling Shredder] has been the recipient of numerous industry awards and accolades. The company has also been recognized for its outstanding customer service and support, solidifying its reputation as a trusted and reliable partner in the recycling and waste management industry.Looking ahead, [Recycling Shredder] is poised to continue leading the way in sustainable waste management solutions. With a focus on innovation, sustainability, and customer satisfaction, the company is well-positioned to address the growing global demand for efficient and effective recycling and waste shredding solutions.As the world continues to prioritize environmental sustainability, [Recycling Shredder] is committed to playing a vital role in helping businesses and organizations meet their recycling and waste management objectives. With its advanced machinery, dedication to innovation, and comprehensive support services, [Recycling Shredder] is setting the standard for sustainable waste management solutions around the world.

Efficient Plastic Shredder Machine for Recycling and Waste Management

Plastic pollution has been a major issue for many years, with massive amounts of plastic waste ending up in landfills, waterways, and oceans. To combat this problem, many companies have been working on developing innovative solutions to recycle and dispose of plastic waste responsibly. One such company is {Need to remove brand name}, a leader in the field of sustainable waste management.{Need to remove brand name} is renowned for its cutting-edge technologies and solutions for recycling plastic waste. The company has been at the forefront of developing environmentally-friendly machines that are designed to efficiently process and recycle plastic waste. One of their most notable products is the Plastic Shredder Machine, which has garnered attention for its efficiency and sustainability.The Plastic Shredder Machine is a powerful and versatile tool that is designed to quickly and effectively shred plastic waste into smaller pieces. This process is essential for recycling plastic, as it allows for the material to be easily transformed into new products. The machine is equipped with sharp blades and a high-powered motor, allowing it to shred large volumes of plastic waste with ease.One of the key features of the Plastic Shredder Machine is its ability to handle various types of plastic waste, including bottles, containers, packaging, and more. This versatility makes it a valuable asset for recycling facilities, as it can effectively process different types of plastic materials, reducing the need for manual sorting and processing.In addition to its efficiency, the Plastic Shredder Machine is also designed with sustainability in mind. The machine is equipped with advanced safety features to ensure the protection of the operators and the environment. It also has a robust build quality, ensuring long-term reliability and minimal maintenance requirements.{Need to remove brand name} is committed to promoting sustainability and environmental responsibility through its products and services. The Plastic Shredder Machine is just one of the many innovative solutions that the company offers to help tackle plastic pollution. In addition to the shredder, the company also provides a range of recycling equipment and machinery designed to facilitate the recycling process and minimize the environmental impact of plastic waste.The Plastic Shredder Machine has already made a significant impact in the recycling industry, with many businesses and organizations investing in this innovative technology to enhance their plastic recycling capabilities. By implementing the machine into their operations, these entities have been able to increase their plastic recycling rates and reduce the amount of plastic waste that ends up in landfills or pollutes the environment.Furthermore, {Need to remove brand name} offers comprehensive support and services to ensure that their customers can maximize the benefits of the Plastic Shredder Machine. From installation and training to maintenance and technical support, the company is dedicated to assisting their clients in optimizing their plastic recycling processes and achieving their sustainability goals.As the global demand for sustainable waste management solutions continues to grow, {Need to remove brand name} remains at the forefront of the industry, continually innovating and developing new technologies to address the challenges of plastic pollution. With the Plastic Shredder Machine and their other cutting-edge solutions, the company is making a significant contribution to the fight against plastic waste, promoting a more sustainable and environmentally-friendly future for generations to come.