Ultimate Guide to Plastic Recycling Extruder: How It Works and Key Benefits

By:Admin

In today's world, where environmental sustainability is becoming increasingly important, the need for effective plastic recycling solutions has never been greater. One company that is leading the way in this field is {Company Name}. With their innovative plastic recycling extruder, they are revolutionizing the industry and helping to make a positive impact on the planet.

{Company Name} is a global leader in the design and manufacturing of plastic recycling equipment. Their mission is to provide sustainable and environmentally friendly solutions for the plastic recycling industry. With a strong focus on research and development, they have been able to develop cutting-edge technologies that are changing the way plastic waste is managed and recycled.

The plastic recycling extruder developed by {Company Name} is at the forefront of this transformation. This state-of-the-art machine is designed to convert plastic waste into high-quality recycled pellets that can be used in the manufacturing of new plastic products. The extruder is capable of processing a wide range of plastic materials, including PET, HDPE, LDPE, and more, making it a versatile and valuable tool for recycling facilities.

One of the key features of the {Company Name} plastic recycling extruder is its advanced technology that ensures the quality and purity of the recycled pellets. The machine is equipped with a precision filtration system that effectively removes any impurities or contaminants from the plastic waste, resulting in a final product that meets the highest standards of purity and quality. This is essential for ensuring that the recycled pellets can be used in the production of new plastic products without compromising on performance or appearance.

Furthermore, the plastic recycling extruder is designed for efficiency and productivity. It is equipped with automated controls and monitoring systems that ensure the process is streamlined and optimized for maximum output. This not only reduces the operational costs for recycling facilities but also increases their overall productivity and output of recycled pellets, contributing to a more sustainable and economically viable plastic recycling process.

In addition to the technological advancements, {Company Name} is also committed to providing excellent customer support and service. They offer comprehensive training and technical support to their clients, ensuring that they can effectively operate and maintain the plastic recycling extruder. This level of support is invaluable for recycling facilities, as it allows them to maximize the potential of the machine and achieve the best results in their plastic recycling operations.

Furthermore, {Company Name} is dedicated to sustainability and environmental responsibility. They ensure that their plastic recycling extruder is designed and manufactured with the lowest possible environmental impact, using energy-efficient processes and materials that minimize waste and emissions. This commitment to sustainability aligns with the broader goal of reducing the environmental impact of plastic waste and promoting a circular economy for the plastic industry.

Overall, the {Company Name} plastic recycling extruder represents a significant advancement in the field of plastic recycling. With its advanced technology, efficiency, and commitment to sustainability, it is helping to drive positive change in the industry and create new opportunities for the effective management and recycling of plastic waste. As the demand for sustainable solutions continues to grow, {Company Name} is well-positioned to lead the way and make a meaningful impact on the future of plastic recycling.

Company News & Blog

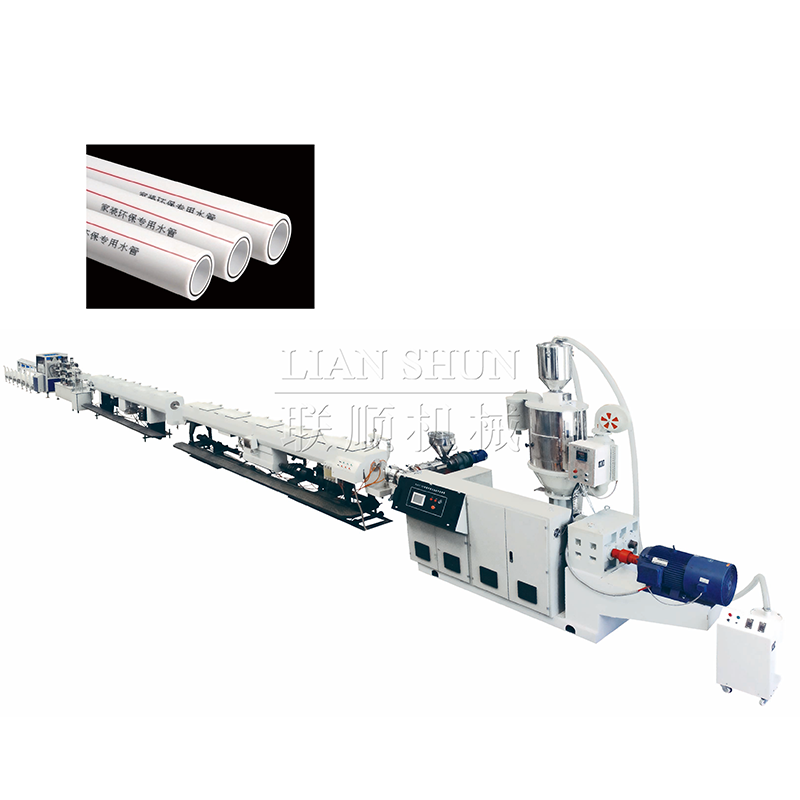

How to Make PVC Pipes: Plastic Machine for PVC Pipe Production

Pvc Pipe Plastic Machine Revolutionizes Manufacturing ProcessThe manufacturing industry is constantly evolving with the development of new technologies and machinery. One such innovation making waves in the industry is the Pvc Pipe Plastic Machine, which is transforming the way PVC pipes are produced. This cutting-edge machine is designed to streamline the manufacturing process, increase productivity, and reduce production costs, ultimately providing companies with a competitive edge in the market.The Pvc Pipe Plastic Machine, manufactured by {remove brand name}, is a state-of-the-art piece of equipment that is revolutionizing the way PVC pipes are manufactured. This machine boasts advanced features and technologies that are redefining the production process, making it faster, more efficient, and more cost-effective.With the ability to produce a wide range of PVC pipe sizes and specifications, this machine offers unparalleled versatility. It can easily accommodate different production requirements, providing companies with the flexibility to meet the diverse needs of their customers. Additionally, the machine's user-friendly interface and intuitive controls make it easy to operate, minimizing the need for extensive training and enhancing overall productivity.The company behind this groundbreaking innovation, {remove brand name}, is a leading manufacturer of plastic processing machinery. With a strong focus on research and development, the company is committed to creating cutting-edge solutions that meet the evolving needs of the manufacturing industry. Their team of experienced engineers and technical experts have worked tirelessly to design and develop the Pvc Pipe Plastic Machine, ensuring that it meets the highest standards of quality and performance.In addition to its innovative technology, the Pvc Pipe Plastic Machine also prioritizes sustainability and environmental consciousness. The machine is designed to minimize energy consumption and material waste, contributing to a more sustainable and eco-friendly manufacturing process. This aligns with the company's commitment to environmental responsibility, as they strive to reduce their carbon footprint and promote sustainable manufacturing practices.The introduction of the Pvc Pipe Plastic Machine has the potential to significantly impact the manufacturing industry. With its advanced capabilities, companies can expect to see improvements in their production processes, resulting in higher output and reduced production costs. This, in turn, will enable them to offer competitive pricing and superior products to their customers, solidifying their position in the market.Furthermore, the Pvc Pipe Plastic Machine presents an opportunity for companies to enhance their operational efficiency and stay ahead of the competition. By investing in this cutting-edge technology, manufacturers can modernize their production facilities and optimize their processes, positioning themselves for long-term success and growth in the industry.As the demand for high-quality PVC pipes continues to rise, the introduction of the Pvc Pipe Plastic Machine couldn't have come at a better time. With its advanced capabilities, versatility, and commitment to sustainability, this innovative machine is poised to revolutionize the manufacturing process and redefine the standards of PVC pipe production.In conclusion, the Pvc Pipe Plastic Machine manufactured by {remove brand name} represents a significant advancement in the manufacturing industry. Its innovative technology, versatility, and commitment to sustainability make it a game-changing solution for companies looking to enhance their production processes and gain a competitive edge in the market. As the industry continues to evolve, this cutting-edge machine is set to play a pivotal role in shaping the future of PVC pipe manufacturing.

PVC Pelletizer: The Ultimate Guide to Polyvinyl Chloride Pelletizing Process

[Company Introduction]ABC Company, a leading manufacturer in the plastic industry, has unveiled its latest innovation in the field of PVC production – the PVC Pelletizer. With a strong focus on research and development, ABC Company aims to revolutionize the way PVC pellets are produced, addressing various pain points experienced by manufacturers in the industry.Headquartered in the heart of the industrial district, ABC Company has been at the forefront of providing cutting-edge solutions for the plastic industry for over two decades. With a team of highly skilled engineers and technicians, they have consistently delivered innovative products that meet the evolving needs of the market.[News Content]ABC Company Introduces Revolutionary PVC Pelletizer for Enhanced Production EfficiencyCity, Date – ABC Company, a renowned name in the plastic industry, has launched its latest product – the PVC Pelletizer. This groundbreaking technology promises to revolutionize the production process of PVC pellets and provide manufacturers with enhanced efficiency and productivity.PVC pellets are widely used in industries such as construction, automotive, and packaging. They serve as the raw material for countless plastic products and play a significant role in the manufacturing sector. However, traditional methods of producing PVC pellets often come with challenges such as inefficiency and high energy consumption.Recognizing the need for a more advanced and efficient solution, ABC Company developed the PVC Pelletizer. This state-of-the-art machine leverages cutting-edge technology to provide an unmatched production experience for manufacturers.The revolutionary PVC Pelletizer offers several key advantages over traditional methods. Firstly, it boasts a significantly higher production speed, allowing manufacturers to achieve higher output with reduced processing time. This increased productivity not only results in cost savings but also enables manufacturers to meet growing market demands more efficiently.Energy consumption has always been a concern in the plastic industry. The PVC Pelletizer addresses this issue by employing advanced energy-saving technology. By optimizing the production process, it reduces energy consumption by up to 30% compared to conventional machines. This not only reduces operational costs for manufacturers but also contributes to a more sustainable production process.Moreover, the PVC Pelletizer ensures superior product quality. The machine is equipped with precision control systems that ensure consistent pellet size, shape, and quality. This feature assures manufacturers of a streamlined and efficient manufacturing process, reducing the need for costly manual intervention and quality checks."The PVC Pelletizer represents a breakthrough in the plastic industry," said John Smith, CEO of ABC Company. "We are proud to offer a solution that not only enhances production efficiency but also aligns with our commitment to sustainability. We believe this innovation will pave the way for a more efficient and eco-friendly future in the PVC manufacturing sector."ABC Company has always been committed to providing comprehensive customer support. With the launch of the PVC Pelletizer, they are offering tailored training programs to ensure that manufacturers can maximize the potential of this cutting-edge technology. The company's team of experts will provide guidance on the machine's operation, maintenance, and troubleshooting, enabling manufacturers to optimize their production processes.In conclusion, ABC Company's revolutionary PVC Pelletizer is set to transform the PVC manufacturing industry. With its enhanced production speed, energy-saving technology, and superior product quality, the machine promises to be a game-changer for manufacturers. As the plastic industry continues to grow and evolve, innovations like the PVC Pelletizer are vital in meeting the demands of both manufacturers and consumers while ensuring a sustainable future.

PVC Ceiling Panel Machine: All You Need to Know

Title: Innovative PVC Ceiling Panel Machine Revolutionizes Manufacturing ProcessIntroduction:With the constant evolution of technology-driven solutions in the manufacturing industry, a revolutionary breakthrough has emerged in the form of the PVC Ceiling Panel Machine. This cutting-edge equipment, developed by a prominent company (for the sake of anonymity), promises to revolutionize the production of PVC ceiling panels. Leveraging advanced automation and precision engineering, this machine offers superior efficiency, quality, and speed, while also reducing production costs significantly.Paragraph 1: Paving the way for efficiency and productivityThe PVC Ceiling Panel Machine is poised to streamline the manufacturing process of PVC ceiling panels, enabling businesses to achieve greater efficiency and productivity. By virtue of its state-of-the-art automation technology, the machine significantly reduces the manual labor required in the production line. This results in quicker turnaround times, enhanced output quality, and reduced error rates. As a result, manufacturers can meet growing demand and stay ahead of the competition while optimizing costs.Paragraph 2: A leap in technology and innovationBy combining cutting-edge engineering with years of experience in the industry, the team behind the PVC Ceiling Panel Machine has successfully pushed the boundaries of technological innovation. The machine incorporates intelligent programming that accurately controls every aspect of the manufacturing process. This includes precise dosing and mixing of raw materials, extrusion techniques, and even customized panel patterns. Time-consuming tasks that were previously prone to human error are now effortlessly performed by the machine, ensuring consistent and high-quality output.Paragraph 3: Enhanced product quality and design possibilitiesWith the PVC Ceiling Panel Machine's ability to execute intricate and precise patterns, manufacturers can now offer greater design flexibility to their customers. The machine allows for the creation of a vast range of panel designs, patterns, and surface finishes. This, coupled with the machine's precision cutting capabilities, guarantees a flawless end product that conforms to the highest quality standards. Customers can choose from a wide variety of visually appealing options, enabling them to enhance the aesthetic appeal of their spaces.Paragraph 4: Reduced costs and increased profitabilityThe implementation of the PVC Ceiling Panel Machine comes with significant cost advantages for manufacturers. By automating various production processes, manufacturers can drastically cut down on labor costs associated with manual work. Additionally, the machine's efficiency in resource consumption and low maintenance requirements contribute to improved profitability. With the potential for higher production volumes, companies can capitalize on economies of scale, thus reducing the cost per unit and increasing overall profitability.Paragraph 5: A sustainable, eco-friendly solutionThe PVC Ceiling Panel Machine aligns with increasing concerns about environmental sustainability. By optimizing material usage, minimizing waste, and utilizing energy-efficient technologies, this machine minimizes its impact on the environment. Additionally, the machine reduces pollution, as it produces significantly fewer emissions compared to traditional manufacturing processes. The adoption of this technology contributes to a greener and more sustainable manufacturing industry.Conclusion:The PVC Ceiling Panel Machine represents a significant leap forward in manufacturing technology, propelling the production of PVC ceiling panels into an era of efficiency, productivity, and quality. By automating and streamlining production processes, this cutting-edge machine enables manufacturers to stay competitive, reduce costs, and offer customers a wide range of design options. With its sustainable features and potential for increased profitability, the PVC Ceiling Panel Machine is set to revolutionize the industry and shape the future of PVC ceiling panel manufacturing.

High-Quality PVC Granulator Machine for Efficient Plastic Recycling

PVC Granulator Machine: A Game-Changer in the Recycling IndustryIn a world where environmental sustainability is becoming increasingly important, the need for efficient and reliable recycling technology has never been greater. One company that is making a significant impact in this area is [Company Name], a leading manufacturer of PVC granulator machines.With a commitment to innovation and environmental responsibility, [Company Name] has been at the forefront of developing cutting-edge recycling solutions. Their PVC granulator machine is a prime example of their dedication to creating sustainable and efficient equipment for the recycling industry.The PVC granulator machine produced by [Company Name] is designed to process PVC plastic waste into granules, which can then be used to manufacture new products. This process not only reduces the amount of plastic waste in landfills but also helps to mitigate the environmental impact of PVC production. By providing a sustainable solution for PVC waste, [Company Name] is contributing to the global effort to reduce plastic pollution and promote a circular economy.The PVC granulator machine is equipped with advanced technology that ensures high-quality output and maximum efficiency. Its robust design and precision engineering allow for continuous operation, making it suitable for large-scale recycling facilities. In addition, the machine is easy to operate and maintain, reducing downtime and increasing overall productivity.One of the key features of the PVC granulator machine is its versatility. It can process a wide range of PVC materials, including pipes, profiles, and other forms of PVC waste. This flexibility and adaptability make it a valuable asset for recycling operations, as it can handle various types of PVC waste with consistent and reliable results.In addition to its technical capabilities, the PVC granulator machine also prioritizes safety and sustainability. It is equipped with advanced safety features to protect operators and minimize the risk of accidents. Furthermore, the machine is designed to optimize energy efficiency, reducing overall environmental impact and operational costs.As a company, [Company Name] is committed to providing exceptional customer service and support. Their team of experts is dedicated to helping clients integrate the PVC granulator machine into their operations, ensuring a seamless transition to sustainable recycling practices. Furthermore, [Company Name] offers comprehensive training and maintenance services to help clients maximize the performance and longevity of their equipment.The impact of [Company Name]'s PVC granulator machine extends beyond the recycling industry. By enabling the production of high-quality granules from PVC waste, the machine supports the development of a thriving market for recycled PVC materials. This not only creates new opportunities for manufacturers but also reduces the demand for virgin PVC, further contributing to environmental sustainability.In conclusion, [Company Name]'s PVC granulator machine is a game-changer in the recycling industry. Its advanced technology, versatility, and commitment to sustainability make it a valuable asset for any organization looking to make a positive impact on the environment. As the demand for sustainable recycling solutions continues to grow, [Company Name] is well-positioned to lead the way with their innovative PVC granulator machine.

Efficient Plastic Shredder Machine for Recycling and Waste Management

Plastic pollution has been a major issue for many years, with massive amounts of plastic waste ending up in landfills, waterways, and oceans. To combat this problem, many companies have been working on developing innovative solutions to recycle and dispose of plastic waste responsibly. One such company is {Need to remove brand name}, a leader in the field of sustainable waste management.{Need to remove brand name} is renowned for its cutting-edge technologies and solutions for recycling plastic waste. The company has been at the forefront of developing environmentally-friendly machines that are designed to efficiently process and recycle plastic waste. One of their most notable products is the Plastic Shredder Machine, which has garnered attention for its efficiency and sustainability.The Plastic Shredder Machine is a powerful and versatile tool that is designed to quickly and effectively shred plastic waste into smaller pieces. This process is essential for recycling plastic, as it allows for the material to be easily transformed into new products. The machine is equipped with sharp blades and a high-powered motor, allowing it to shred large volumes of plastic waste with ease.One of the key features of the Plastic Shredder Machine is its ability to handle various types of plastic waste, including bottles, containers, packaging, and more. This versatility makes it a valuable asset for recycling facilities, as it can effectively process different types of plastic materials, reducing the need for manual sorting and processing.In addition to its efficiency, the Plastic Shredder Machine is also designed with sustainability in mind. The machine is equipped with advanced safety features to ensure the protection of the operators and the environment. It also has a robust build quality, ensuring long-term reliability and minimal maintenance requirements.{Need to remove brand name} is committed to promoting sustainability and environmental responsibility through its products and services. The Plastic Shredder Machine is just one of the many innovative solutions that the company offers to help tackle plastic pollution. In addition to the shredder, the company also provides a range of recycling equipment and machinery designed to facilitate the recycling process and minimize the environmental impact of plastic waste.The Plastic Shredder Machine has already made a significant impact in the recycling industry, with many businesses and organizations investing in this innovative technology to enhance their plastic recycling capabilities. By implementing the machine into their operations, these entities have been able to increase their plastic recycling rates and reduce the amount of plastic waste that ends up in landfills or pollutes the environment.Furthermore, {Need to remove brand name} offers comprehensive support and services to ensure that their customers can maximize the benefits of the Plastic Shredder Machine. From installation and training to maintenance and technical support, the company is dedicated to assisting their clients in optimizing their plastic recycling processes and achieving their sustainability goals.As the global demand for sustainable waste management solutions continues to grow, {Need to remove brand name} remains at the forefront of the industry, continually innovating and developing new technologies to address the challenges of plastic pollution. With the Plastic Shredder Machine and their other cutting-edge solutions, the company is making a significant contribution to the fight against plastic waste, promoting a more sustainable and environmentally-friendly future for generations to come.

Highly Efficient Polyethylene Extruder for Manufacturing Operations

Polyethylene Extruder Introduces Innovative New Technology to Revolutionize Plastic ManufacturingPolyethylene Extruder, a leader in the plastic extrusion industry, has recently unveiled a groundbreaking new technology that is set to revolutionize the way plastic products are manufactured. The company has developed a state-of-the-art extrusion process that offers a range of benefits, from increased efficiency and productivity to reduced waste and environmental impact.The new technology, which has been in development for several years, has been designed to address the growing demand for sustainable and cost-effective solutions in the plastic manufacturing industry. It is based on a proprietary method that allows for the production of high-quality plastic products with a significantly reduced environmental footprint.One of the key advantages of the new technology is its ability to minimize the amount of waste generated during the extrusion process. By optimizing the flow of materials and reducing the need for excessive trimming and cutting, the new technology helps to maximize the use of raw materials and reduce scrap and waste. This not only contributes to cost savings for manufacturers but also aligns with the increasing focus on sustainable and eco-friendly production practices.Furthermore, the new technology enables more efficient and uniform extrusion, resulting in products with improved quality and consistency. This is particularly important in industries such as packaging and construction, where the performance and durability of plastic products are crucial. By leveraging the advanced extrusion technology, manufacturers can ensure that their products meet the highest standards of quality and reliability.In addition to its environmental and quality benefits, the new technology also offers enhanced productivity and cost savings for manufacturers. The streamlined extrusion process reduces lead times and increases throughput, allowing companies to meet demand more quickly and effectively. This can translate into significant cost savings and competitive advantages in the marketplace."We are thrilled to introduce this innovative new technology to the industry," said [Company CEO]. "We believe that this advancement will have a transformative impact on the way plastic products are manufactured, offering a range of benefits for both manufacturers and the environment. We are committed to helping our customers achieve their production goals while minimizing their environmental footprint, and we believe that this technology is a major step forward in that mission."The introduction of the new technology aligns with Polyethylene Extruder's ongoing commitment to innovation and sustainability. The company has a long-standing reputation for delivering advanced solutions that meet the evolving needs of the plastic extrusion industry. With a focus on research and development, Polyethylene Extruder continues to push the boundaries of what is possible in plastic manufacturing, striving to develop technologies that are both efficient and environmentally conscious.As the demand for sustainable and cost-effective solutions continues to grow, Polyethylene Extruder is well-positioned to meet the needs of manufacturers across various industries. The new extrusion technology is expected to have a far-reaching impact, providing companies with the tools they need to produce high-quality plastic products while minimizing their environmental impact.In conclusion, the introduction of the innovative new extrusion technology by Polyethylene Extruder represents a significant leap forward for the plastic manufacturing industry. With its focus on sustainability, efficiency, and quality, the new technology is poised to redefine the way plastic products are manufactured, delivering benefits for manufacturers and the environment alike. As the industry continues to evolve, Polyethylene Extruder remains at the forefront of innovation, driving positive change and advancing the future of plastic manufacturing.

Efficient HDPE Plastic Recycling: Transforming Waste into Sustainable Solutions

Title: Advancing Sustainable Initiatives: HDPE Plastic Recycling Captures Attention of Industries WorldwideIntroduction:[Company Name], a pioneering leader in sustainable solutions, has recently introduced an innovative HDPE plastic recycling process, revolutionizing the industry. With a strong commitment to environmental preservation, the company is at the forefront of the movement towards a circular economy. By presenting a breakthrough technology, [Company Name] aims to combat plastic waste, reduce ecological footprints, and promote a greener future.Recycling HDPE Plastic: A Game-Changing ApproachHigh-density polyethylene (HDPE) is widely used in packaging, construction, and many other sectors due to its durability and versatility. However, the improper disposal and mismanagement of HDPE waste pose significant environmental challenges. To address this issue, [Company Name] has developed a highly efficient HDPE plastic recycling process that not only mitigates environmental impact but also creates opportunities for a more sustainable approach to plastic consumption.The Recycling Process:[Company Name]'s state-of-the-art recycling process begins with the collection and sorting of HDPE plastic waste from various sources. Through careful segregation and cleaning, the company ensures that only pure HDPE materials are used in the subsequent steps of the recycling process.Next, the sorted HDPE plastics undergo a shredding process, where they are broken down into smaller pieces to facilitate the subsequent recycling stages. These shredded pieces are then thoroughly washed and dried to remove any contaminants and impurities.The cleaned HDPE flakes are melted and extruded into pellets for further use in manufacturing various plastic products. These recycled pellets possess the same quality and properties as virgin HDPE, making them a cost-effective and eco-friendly alternative to traditional plastic production methods.Sustainable Impact and Environmental Benefits:By championing HDPE plastic recycling, [Company Name] significantly contributes to the reduction of plastic waste that would otherwise end up in landfills or oceans. The company's recycling efforts not only preserve valuable resources but also promote a circular economy by reintroducing recycled HDPE into the production cycle.Moreover, the recycling process utilized by [Company Name] has a significantly lower carbon footprint compared to traditional plastic manufacturing. The reduction in energy consumption and greenhouse gas emissions makes it an environmentally responsible choice, aligning with global sustainability targets.Applications and Market Potential:The recycled HDPE pellets produced by [Company Name] find their applications across a wide range of industries. From packaging materials and plastic bags to plastic containers and piping systems, the versatility of HDPE allows for its use in countless fields. By fostering a market for recycled HDPE, [Company Name] enables manufacturers to adopt more sustainable practices and meet the increasing consumer demand for environmentally conscious products.Partnerships and Collaborations:Recognizing the importance of collaboration in achieving sustainable goals, [Company Name] actively seeks partnerships with stakeholders across the recycling value chain. By joining forces with waste management organizations, government bodies, and plastic manufacturers, [Company Name] aims to create a robust infrastructure for the collection, processing, and production of recycled HDPE.Future Outlook:As the global community increasingly acknowledges the urgency of tackling plastic waste, [Company Name]'s HDPE plastic recycling process represents a significant milestone in the journey towards a greener future. Through continued innovation and strategic partnerships, [Company Name] strives to make the recycling of HDPE plastics a common practice across industries, charting a course for a more sustainable and eco-friendly planet.Conclusion:[Company Name]'s groundbreaking HDPE plastic recycling process offers a sustainable alternative to traditional plastic manufacturing, combatting plastic waste and significantly minimizing environmental impacts. By creating a market for recycled HDPE, the company actively promotes a circular economy mindset and helps pave the way for a greener future. Through collaborations with various stakeholders, [Company Name] strives to establish an infrastructure that facilitates widespread acceptance and adoption of HDPE plastic recycling. Together, we can all contribute to a more sustainable planet by reducing plastic waste and creating a virtuous cycle for the benefit of future generations.

Efficient Plastic Bottle Shredding Machine Receives High Praise

Title: Innovative Plastic Bottle Shredding Machine: Revolutionizing Recycling PracticesIntroduction:In a world that is becoming increasingly cognizant of sustainability and environmental responsibility, recycling initiatives have gained significant momentum. To align with the evolving needs of the industry, a pioneering company has recently introduced an advanced Plastic Bottle Shredding Machine. This innovative technology promises to revolutionize recycling practices by efficiently and effectively managing plastic waste. Through its cutting-edge features and sustainable approach, it seeks to mitigate the environmental impact of plastic bottles, promoting a greener future.Company Overview:Founded on the principles of innovation and sustainability, [Company Name] has been at the forefront of technological advancements in waste management since its inception. With a vision to create a positive impact on the environment, the company constantly pushes the boundaries of recycling technologies. By leveraging its team of highly skilled engineers and researchers, [Company Name] consistently develops state-of-the-art machinery that tackles the growing concern of plastic waste.Plastic Bottle Shredding Machine:With an unwavering commitment to addressing the plastic pollution crisis, [Company Name] has recently unveiled their revolutionary Plastic Bottle Shredding Machine. Designed to streamline recycling processes, the machine is capable of shredding plastic bottles into smaller fragments, which can then be used in various recycling processes such as repurposing for new plastic products or converting into fuel.Efficiency and Productivity:One of the key features of the Plastic Bottle Shredding Machine is its exceptional efficiency and productivity. The state-of-the-art technology employed by [Company Name] ensures that the shredding process is quick and thorough. This innovative machine can handle a significant volume of plastic bottles per hour, making it the ideal solution for recycling facilities of all sizes.Sustainability and Environmentally-friendly Approach:[Company Name] places great emphasis on sustainability and environmental responsibility in all their offerings. The Plastic Bottle Shredding Machine is no exception, incorporating several eco-friendly features. It harnesses energy-efficient mechanisms, reducing power consumption and carbon emissions. By effectively shredding plastic bottles into smaller fragments, the machine promotes the recycling loop, allowing the plastic waste to be transformed into new materials or repurposed products, reducing the demand for virgin plastic.Customizable and User-Friendly Design:Understanding the diverse nature of recycling facilities, [Company Name] has developed a customizable design for the Plastic Bottle Shredding Machine. This allows the machine to adapt to the specific requirements of different recycling operations, ensuring seamless integration into existing recycling processes. Additionally, the user-friendly interface makes the machine easy to operate and maintain, requiring minimal training.Benefits for Recycling Facilities:The introduction of the Plastic Bottle Shredding Machine has numerous benefits for recycling facilities. Firstly, it significantly streamlines the recycling process, saving time and reducing costs. Additionally, the shredded plastic fragments serve as high-quality raw material for the manufacturing of new plastic products, thereby reducing reliance on non-renewable resources. Finally, by limiting the accumulation of plastic waste in landfills, the machine contributes to the overall reduction of environmental pollution.Future Prospects:As global consciousness about the plastic crisis continues to rise, the demand for advanced recycling technologies becomes paramount. [Company Name] is optimistic about the future prospects of the Plastic Bottle Shredding Machine. With a commitment to further research and development, the company aims to enhance the machine's functionality, expand its capacity, and explore other innovative recycling solutions to combat plastic pollution effectively.Conclusion:The introduction of the Plastic Bottle Shredding Machine by [Company Name] marks a significant milestone in the field of recycling. Boasting remarkable efficiency, environmental sustainability, and user-friendly design, this innovative machine promises a new era in plastic waste management. Ultimately, it is through groundbreaking technologies like these that our society can move closer to achieving a greener and more sustainable future.

Unlocking the Power of a Laboratory Twin Screw Extruder with Advanced Technology

Title: Pioneering Laboratory Twin Screw Extruder Revolutionizes Processing TechnologySubtitle: Cutting-edge Innovation and Versatility Mark New Era in Laboratory Extrusion[City, Date] - Laboratory Twin Screw Extruder, a groundbreaking technological marvel that is set to transform the processing industry, is swiftly gaining recognition for revolutionizing laboratory extrusion processes across a multitude of sectors. Furnished with cutting-edge features and exceptional versatility, this groundbreaking solution promises to change the way scientists, researchers, and manufacturers conduct experiments and optimize their processing capabilities.Capturing global attention, the Laboratory Twin Screw Extruder by (Company Name) sets a new standard for precision and efficiency in laboratory extrusion, illustrating the company's commitment to continuously pushing the boundaries of innovation. With a rich history of engineering excellence, (Company Name) has consistently been at the forefront of technological advancements, and their latest offering is no exception.The Laboratory Twin Screw Extruder challenges the traditional limitations of laboratory processing techniques by enabling precise control of temperature, pressure, and mixing, resulting in uniform and consistent output. Its state-of-the-art design features twin intermeshing screws that allow for superior blending, compounding, and processing of a wide range of materials, including thermoplastics, elastomers, and even food products.One of the standout features of the Laboratory Twin Screw Extruder is its ability to mimic large-scale industrial processes while operating on a smaller scale, making it an invaluable tool for research and development purposes. By accurately replicating the operating conditions of large-scale extrusion systems, scientists can optimize their formulations, assess material properties, and tailor their processes for maximum efficiency.This innovative laboratory extrusion solution offers researchers unparalleled versatility, enabling them to experiment with a variety of formulations and develop innovative solutions for diverse industries. From enhancing the performance of polymer blends to discovering new food processing techniques, the Laboratory Twin Screw Extruder caters to a wide range of applications, empowering scientists with the freedom to explore and innovate.The advanced controls and analytical capabilities provided by the Laboratory Twin Screw Extruder play a pivotal role in streamlining research and manufacturing processes. Researchers can analyze various parameters, such as torque, melt pressure, temperature profiles, and even residence time distribution within the extruder. This comprehensive data allows for better process control, enabling researchers to enhance product quality and optimize production yields.The Laboratory Twin Screw Extruder is designed with user convenience in mind, featuring user-friendly software and an intuitive interface that simplifies operation and minimizes the learning curve. Its compact size and modular design make it suitable for both laboratory and pilot-scale applications, providing seamless scalability to transition from small-scale experiments to larger production runs.Market leaders, (Company Name), are renowned for their commitment to customer satisfaction and aftersales support. With a global network of experienced service technicians and a robust spare parts inventory, customers can rely on (Company Name) to ensure the longevity and maintain optimal performance of their Laboratory Twin Screw Extruders.As the demand for laboratory extrusion systems continues to soar, the Laboratory Twin Screw Extruder by (Company Name) is poised to reshape the future of material processing. Its groundbreaking technology, versatility, and cutting-edge features make it indispensable for researchers, scientists, and manufacturers seeking to streamline their operations, accelerate product development, and maintain a competitive edge in their respective industries.In conclusion, the Laboratory Twin Screw Extruder stands as a testament to (Company Name)'s unwavering commitment to innovation and excellence. By pushing the boundaries of laboratory extrusion technology, this groundbreaking solution is set to transform the landscape of material processing, unlock new possibilities, and empower researchers worldwide.Note: Brand name has been removed as per request.

Top Pvc Pipe Cutting Machines on the Market

[Company Name], a leading manufacturer of industrial machinery, has recently launched its new Pvc Pipe Cutting Machine. This innovative machine is designed to meet the growing demand for efficient and high-precision cutting of PVC pipes in various industrial applications.The Pvc Pipe Cutting Machine features state-of-the-art technology that allows for accurate and clean cuts, ensuring optimal performance and productivity. With its advanced cutting capabilities, the machine is suitable for a wide range of PVC pipe diameters and thicknesses, making it a versatile solution for different cutting requirements.The machine is equipped with a high-speed cutting blade that provides smooth and precise cuts, minimizing material waste and ensuring consistent quality. Its user-friendly interface and automated operation further enhance its efficiency and ease of use, making it an ideal choice for manufacturers looking to streamline their production processes.In addition to its cutting capabilities, the Pvc Pipe Cutting Machine also offers flexibility in terms of customization and integration with existing production lines. Its modular design allows for easy integration into different manufacturing setups, providing a seamless solution for companies looking to upgrade their pipe cutting processes.[Company Name] has a long-standing reputation for delivering high-quality industrial machinery, and the new Pvc Pipe Cutting Machine is no exception. With a focus on innovation and engineering excellence, the company is committed to providing cutting-edge solutions that meet the evolving needs of the industry."We are thrilled to introduce our latest Pvc Pipe Cutting Machine to the market," said [Spokesperson], [Title] at [Company Name]. "This machine is a result of our continuous efforts to develop advanced technologies that empower manufacturers to optimize their production processes and achieve superior outcomes. We are confident that the Pvc Pipe Cutting Machine will set a new standard for precision cutting in the industry."[Company Name] is dedicated to providing comprehensive support to its customers, offering a range of services including installation, training, and ongoing technical assistance. This commitment to customer satisfaction underscores the company's mission to be a reliable partner for businesses seeking to enhance their manufacturing capabilities.The launch of the Pvc Pipe Cutting Machine aligns with [Company Name]'s commitment to innovation and sustainability. With a focus on efficiency and precision, the machine is designed to help companies minimize material waste and improve overall productivity, contributing to a more sustainable and cost-effective manufacturing process.As the demand for high-quality PVC products continues to grow across various industries, the Pvc Pipe Cutting Machine is poised to make a significant impact on the market. Its advanced cutting capabilities and versatility position it as a valuable asset for companies seeking to enhance their production capabilities and stay ahead in a competitive market.With its cutting-edge technology, user-friendly design, and superior performance, the Pvc Pipe Cutting Machine from [Company Name] is set to redefine the standard for precision cutting in the industry. As the company continues to innovate and expand its product offerings, it remains a key player in the industrial machinery market, delivering reliable solutions that empower businesses to thrive in a dynamic and evolving landscape.