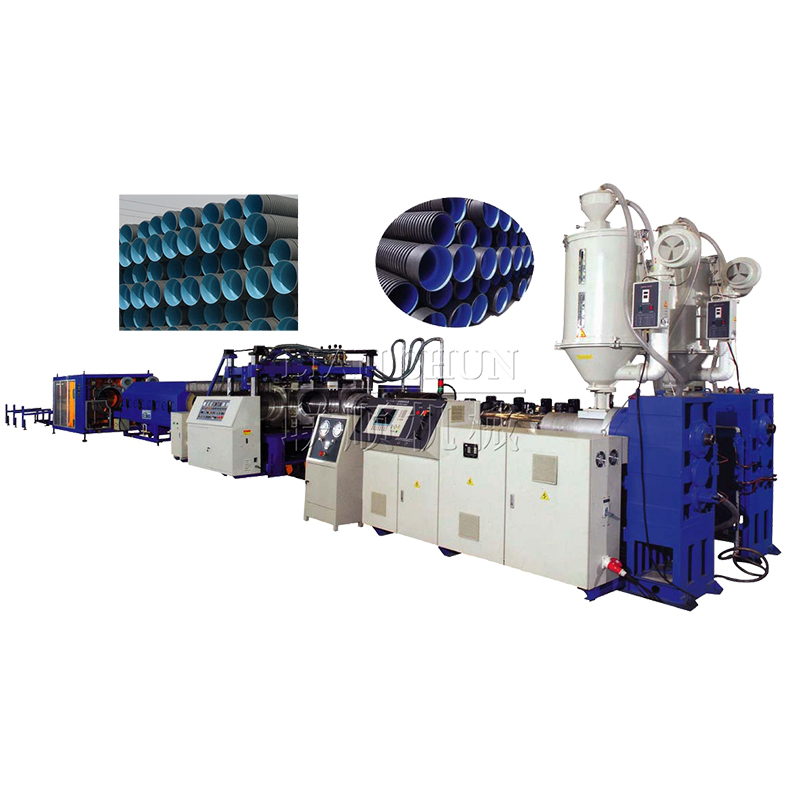

High Quality Pipe Extrusion Machine for PE Material

By:Admin

The plastic industry has seen rapid development in recent years, with the demand for high-quality plastic products continuously increasing. In order to meet this demand, modern technology and machinery are essential. One company that is leading the way in this industry is {}.

{} has been a key player in the plastic machinery industry for over 20 years, specializing in the design, manufacturing, and sale of plastic extrusion machinery. With a strong commitment to innovation and quality, the company has continuously developed new and advanced products to meet the evolving needs of the market.

One of {}'s latest innovations is the Pe Pipe Extrusion Machine, which has revolutionized the plastic industry. This machine is specifically designed for the production of high-quality PE pipes, which are widely used in various applications such as water supply, gas transportation, and agricultural irrigation.

The Pe Pipe Extrusion Machine is equipped with the latest technology and features, ensuring optimal performance and efficiency. It is capable of producing pipes with diameters ranging from 16mm to 800mm, meeting the diverse needs of the market. The machine also offers a high degree of automation, allowing for easy operation and minimal human intervention. This not only improves productivity but also reduces labor costs for manufacturers.

Moreover, the machine is designed with a focus on energy efficiency, utilizing advanced heating and cooling systems to minimize energy consumption. This not only reduces operational costs for manufacturers but also contributes to environmental sustainability.

In addition to its technical capabilities, the Pe Pipe Extrusion Machine is also highly versatile, allowing for the production of various types of PE pipes, including PE80 and PE100. This versatility enables manufacturers to cater to a wide range of applications, further enhancing the machine's value in the market.

With its cutting-edge technology and superior performance, the Pe Pipe Extrusion Machine has quickly gained recognition and popularity in the plastic industry. It has set a new benchmark for the production of PE pipes, offering manufacturers a reliable and efficient solution for meeting the increasing demand for high-quality plastic products.

In line with its commitment to customer satisfaction and support, {} provides comprehensive services for the Pe Pipe Extrusion Machine, including installation, training, and after-sales support. This ensures that customers can fully leverage the capabilities of the machine and maximize their production efficiency.

Furthermore, {}'s dedication to innovation extends beyond its products, with a strong focus on research and development. The company continually invests in research and technology to further enhance the performance and capabilities of its machinery, ensuring that it remains at the forefront of the industry.

As the plastic industry continues to evolve, the demand for advanced machinery and technology will only grow stronger. With its Pe Pipe Extrusion Machine and ongoing commitment to innovation, {} is well-positioned to lead the plastic extrusion industry into a new era of efficiency and productivity.

In conclusion, the Pe Pipe Extrusion Machine from {} represents a significant advancement in the plastic industry, offering manufacturers a reliable and efficient solution for the production of high-quality PE pipes. With its cutting-edge technology, versatility, and comprehensive support services, the machine has set a new standard for the production of plastic pipes, solidifying {}'s position as a leader in the industry.

Company News & Blog

Top Pellet Machine Extruder for Efficient Processing

Pellet Machine Extruder: Revolutionizing the Agricultural IndustryThe agricultural industry has experienced a revolution with the introduction of advanced technology and machinery to improve efficiency and productivity. One such innovation is the Pellet Machine Extruder, which has completely transformed the way agricultural products are processed and utilized. This state-of-the-art machine, introduced by {Company Name}, has gained widespread recognition for its exceptional performance and reliability in the agricultural sector.{Company Name} is a leading manufacturer and supplier of agricultural machinery, specializing in the production of high-quality pellet machine extruders. With years of experience and expertise in the field, the company has established itself as a trusted name in the industry, catering to the diverse needs of agricultural businesses and farms around the world. The company's commitment to innovation and excellence has set it apart from its competitors, making it a preferred choice for farmers and agricultural professionals.The Pellet Machine Extruder offered by {Company Name} is designed to meet the growing demand for efficient and cost-effective processing of agricultural products. Whether it is processing feed for livestock, manufacturing wood pellets for heating, or producing biofuels, this versatile machine offers a range of applications to meet the diverse needs of the agricultural sector. Its advanced features and capabilities make it an essential tool for modern agricultural businesses, allowing them to streamline their operations and enhance their overall productivity.One of the key advantages of the Pellet Machine Extruder is its ability to produce high-quality pellets with minimal waste and energy consumption. The machine is equipped with cutting-edge technology and precision engineering, ensuring consistent and uniform output with every batch. This not only improves the overall quality of the end product but also reduces the environmental impact of the production process. As sustainability and eco-friendliness become increasingly important in agriculture, the Pellet Machine Extruder offers a viable solution to meet these demands.In addition to its performance and efficiency, the Pellet Machine Extruder is also known for its user-friendly design and ease of operation. With intuitive controls and automatic features, the machine can be operated with minimal training and supervision, making it accessible to a wide range of users. This has made it especially popular among small and medium-sized farms and agricultural businesses that may have limited resources for specialized training and technical expertise.Furthermore, {Company Name} offers comprehensive technical support and after-sales service to ensure that customers get the most out of their investment in the Pellet Machine Extruder. From installation and training to maintenance and troubleshooting, the company's team of experts is dedicated to providing the necessary assistance and guidance to help customers optimize the performance of their machines.Overall, the Pellet Machine Extruder from {Company Name} has emerged as a game-changer in the agricultural industry, offering a combination of performance, reliability, and sustainability to meet the evolving needs of modern agriculture. With its advanced technology and user-friendly design, it has become an indispensable tool for farmers and agricultural professionals looking to enhance their productivity and efficiency. As the demand for high-quality agricultural products continues to grow, the Pellet Machine Extruder is poised to play a crucial role in shaping the future of the industry.

High-Quality PVC Pipe Extrusion Machine for Efficient Production

PVC Pipe Extrusion Machine Leads the Industry with Innovation and QualityThe PVC pipe extrusion machine is a vital piece of equipment in the manufacturing of PVC pipes, which are essential components in numerous industries including construction, agriculture, and water supply. The latest advancements in PVC pipe extrusion technology have revolutionized the industry, leading to higher productivity, improved quality, and reduced production costs.One company at the forefront of this innovation is {Company Name}. With a long history of providing top-of-the-line PVC pipe extrusion machines, {Company Name} has established itself as a leader in the field. The company's commitment to research and development has led to the creation of cutting-edge equipment that meets the evolving needs of the industry.The PVC pipe extrusion machine produced by {Company Name} features state-of-the-art technology that ensures precision and efficiency in the extrusion process. The machine is designed to handle a wide range of PVC pipe sizes and specifications, allowing manufacturers to produce pipes that meet the diverse requirements of their customers.One of the key features of {Company Name}'s PVC pipe extrusion machine is its high level of automation, which streamlines the production process and minimizes the need for manual intervention. This results in increased productivity and reduced labor costs, making the machine a valuable investment for PVC pipe manufacturers.In addition to its advanced technology, the PVC pipe extrusion machine from {Company Name} is also known for its exceptional quality and durability. The use of high-quality materials and precision engineering ensures that the machine performs reliably, delivering consistent results with minimal maintenance requirements.Another important aspect of {Company Name}'s PVC pipe extrusion machine is its energy efficiency. The machine is designed to minimize energy consumption, helping manufacturers reduce their operating costs and environmental impact.{Company Name} takes pride in providing comprehensive support to its customers, offering installation, training, and technical assistance to ensure optimal performance of its PVC pipe extrusion machines. The company's team of experienced engineers and technicians are dedicated to helping customers maximize the potential of their equipment.With a strong focus on innovation and customer satisfaction, {Company Name} continues to push the boundaries of PVC pipe extrusion technology. The company's commitment to excellence has earned it a reputation as a trusted partner for PVC pipe manufacturers worldwide.In conclusion, the PVC pipe extrusion machine from {Company Name} represents the latest advancements in technology and quality in the industry. With its innovative features, exceptional performance, and comprehensive support, the machine is a game-changer for PVC pipe manufacturers looking to stay ahead in a competitive market. As the demand for PVC pipes continues to grow, {Company Name} remains at the forefront, providing cutting-edge solutions that meet the evolving needs of the industry.

High-Quality Co-Extruder Machine for Efficient Production

Co Extruder Machine Boosts Production Efficiency for Company{Company Name} is excited to introduce its new Co Extruder Machine, a state-of-the-art piece of equipment that is revolutionizing the company's production processes. This innovative machine has enabled {Company Name} to significantly increase efficiency and throughput, leading to a more streamlined and cost-effective production operation.The Co Extruder Machine is a key component in the company's manufacturing process, as it allows for the simultaneous extrusion of multiple materials. This capability has opened up a host of new possibilities for {Company Name}, allowing them to produce a wider range of products than ever before. With the ability to combine different materials in precise proportions, the Co Extruder Machine has enabled the company to develop unique and innovative products that previously would have been impossible to manufacture.One of the key benefits of the Co Extruder Machine is its ability to enhance the quality and consistency of the products produced by {Company Name}. With its advanced technology and precise control systems, the machine ensures that each product meets the company's exacting standards for performance and reliability. This has helped to bolster the company's reputation for delivering high-quality products to its customers, further solidifying its position as a leader in the industry.In addition to improving product quality, the Co Extruder Machine has also had a positive impact on the company's production efficiency. By allowing for the simultaneous extrusion of multiple materials, the machine has significantly reduced the time and labor required to produce each product. This has enabled {Company Name} to increase its overall production capacity, while also reducing the cost per unit produced. As a result, the company has been able to lower its manufacturing costs and improve its overall profitability.Furthermore, the Co Extruder Machine has helped {Company Name} to reduce its environmental impact. By increasing production efficiency, the machine has enabled the company to reduce its energy consumption and waste generation. This aligns with {Company Name}'s commitment to sustainability, and has allowed the company to operate in a more environmentally responsible manner.The introduction of the Co Extruder Machine has positioned {Company Name} for future growth and success. With its ability to produce a wider range of products more efficiently and cost-effectively, the company is well positioned to meet the growing demand for its products in the market. Furthermore, the machine's ability to produce high-quality, consistent products has reinforced {Company Name}'s reputation as a reliable and innovative manufacturer.{Company Name} is excited about the potential of the Co Extruder Machine and its impact on the company's future. With its ability to increase production efficiency, improve product quality, and reduce environmental impact, the machine is a game-changer for {Company Name}. As the company continues to innovate and expand its product offering, the Co Extruder Machine will be a crucial tool in driving its success in the years to come.

High Quality and Affordable PVC Profile Machine Prices

[CompanyName], a leading manufacturer of PVC profile machines, has announced a significant price drop on their high-quality PVC profile machine. The company has reduced the price of their cutting-edge machine in order to make it more accessible to a wider range of customers in the industry.The PVC profile machine is a crucial piece of equipment for companies in the PVC profile manufacturing industry. It is used to efficiently produce various types of PVC profiles, including window and door profiles, as well as decorative profiles. The machine is known for its precision and high output, making it a popular choice for companies looking to streamline their production processes and improve the quality of their products.With the reduced price, [CompanyName] aims to support small and medium-sized companies in the industry who may have previously found the cost of the machine prohibitive. By making the machine more affordable, the company hopes to enable more companies to invest in advanced technology and elevate the standards of PVC profile production across the industry.In addition to the price drop, [CompanyName] is known for its commitment to delivering top-quality machinery and excellent customer service. The company has a team of highly skilled engineers and technicians who are dedicated to providing comprehensive support to customers, from installation and training to after-sales service.[CompanyName] has been in the business of manufacturing PVC profile machines for over a decade, and has built a strong reputation for reliability and innovation. The company is constantly investing in research and development to enhance its product range and stay ahead of the competition. With a focus on cutting-edge technology and superior craftsmanship, [CompanyName] has become a trusted name in the industry.This latest price drop on the PVC profile machine is a clear demonstration of [CompanyName]'s commitment to meeting the evolving needs of its customers. By making the machine more accessible, the company is supporting the growth and success of PVC profile manufacturers, and contributing to the overall advancement of the industry.Customers who are interested in taking advantage of the reduced price on the PVC profile machine are encouraged to get in touch with [CompanyName] for more information. The company's sales team is available to provide detailed product specifications, pricing, and any other information that potential customers may require. With its proven track record and dedication to customer satisfaction, [CompanyName] is poised to be a valuable partner for companies looking to invest in top-of-the-line PVC profile machinery.In conclusion, the price drop on [CompanyName]'s PVC profile machine marks an exciting development for the industry. By offering a more competitive price, the company is empowering more companies to elevate their production standards and achieve greater success. With its unwavering commitment to quality and customer support, [CompanyName] continues to be a leading force in the PVC profile manufacturing sector.

Cost of Building an HDPE Pipe Plant: What You Need to Know

The [Company Name] has recently announced their plans to establish a new high-density polyethylene (HDPE) pipe plant in response to the growing demand for HDPE pipes in both domestic and international markets. The plant is expected to be a significant addition to the company's existing manufacturing capabilities and its strategic location will further bolster its position as a leading producer of HDPE pipes.The decision to invest in a new HDPE pipe plant comes as a result of a thorough market analysis and assessment of future trends in the industry. The company has identified a consistent increase in the demand for HDPE pipes, driven by the infrastructure development, agriculture, and water supply industries. By expanding their production capacity, the company aims to capitalize on this growing market and strengthen its position as a key player in the HDPE pipe industry.The new plant is expected to be equipped with state-of-the-art technology and advanced production processes to ensure high-quality products and efficient manufacturing operations. This will allow the company to meet the increasing demand for HDPE pipes and offer a diverse range of products to cater to various industry requirements. Moreover, the plant will comply with international quality standards and environmental regulations, reflecting the company's commitment to sustainable and responsible manufacturing practices.In terms of capacity, the new plant is projected to significantly increase the company's HDPE pipe production, allowing them to fulfill large-scale orders and serve a wider customer base. This expansion will also create employment opportunities, contributing to the local economy and supporting the company's commitment to social responsibility and community welfare.The [Company Name] has earmarked a substantial capital investment for the establishment of the new HDPE pipe plant, emphasizing their confidence in the long-term growth prospects of the industry. The investment is in line with the company's strategic vision to expand its presence in the global market and provide innovative solutions to meet the evolving needs of their customers.In addition to the economic implications, the new HDPE pipe plant aligns with the company's dedication to technological advancement and product innovation. By leveraging the latest manufacturing technologies and research advancements, the company aims to enhance the performance and durability of their HDPE pipes, ultimately offering superior solutions to their clientele.The establishment of the new plant is also expected to streamline the company's supply chain and logistics operations, enabling them to efficiently cater to the demands of their clients and deliver products in a timely manner. This will further strengthen the company's competitive edge and reinforce its position as a reliable and trusted HDPE pipe supplier in the industry.Overall, the [Company Name]'s decision to invest in a new HDPE pipe plant underscores their commitment to growth, innovation, and sustainability. The plant's strategic location, advanced technology, and increased production capacity will not only benefit the company but also contribute to the overall development of the HDPE pipe industry. With this significant investment, the [Company Name] is poised to set new benchmarks in the manufacturing and supply of HDPE pipes, further solidifying their position as a market leader in the industry.

Top Pelletizer Technology for Efficient Production

The demand for high-quality pelletizers has been increasing in recent years due to their effectiveness in processing various materials into pellets. With the growing demand in the market, it has become increasingly important for companies to provide innovative and reliable pelletizing solutions. {Company Name}, a leading provider of pelletizing equipment, has been at the forefront of developing cutting-edge pelletizers that cater to the specific needs of its customers.{Company Name} has established itself as a trusted name in the industry, with a strong reputation for delivering top-notch pelletizing solutions. The company offers a wide range of pelletizers that are designed to handle different types of materials, including plastics, metals, and biomass. {Company Name}'s pelletizers are known for their high efficiency, reliability, and durability, making them the preferred choice for many businesses across various industries.One of the key highlights of {Company Name}'s pelletizers is their advanced technology, which sets them apart from other products in the market. The company is committed to ongoing research and development to ensure that its pelletizers are equipped with the latest technological advancements. This dedication to innovation has enabled {Company Name} to stay ahead of the curve and continuously improve the performance and capabilities of its pelletizing equipment.In addition to its state-of-the-art technology, {Company Name} takes pride in the superior quality of its pelletizers. The company employs strict quality control measures to ensure that each pelletizer meets the highest standards of excellence. With a focus on precision engineering and meticulous attention to detail, {Company Name} guarantees that its pelletizers deliver outstanding performance and consistent results.Moreover, {Company Name} places a strong emphasis on customization, understanding that every customer has unique requirements when it comes to pelletizing. The company works closely with its clients to tailor its pelletizers to their specific needs, ensuring that they are able to achieve optimal results for their particular applications. This commitment to customization has earned {Company Name} a loyal customer base, as businesses appreciate the flexibility and personalized approach that the company offers.Furthermore, {Company Name} is dedicated to providing comprehensive support and service to its customers. The company's team of experts is readily available to offer technical guidance, training, and maintenance services to ensure that its customers are able to maximize the performance and lifespan of their pelletizers. {Company Name} takes a proactive approach to customer service, establishing strong relationships with its clients and always being ready to address any concerns or issues that may arise.With the increasing demand for pelletizers in various industries, {Company Name} has positioned itself as a reliable and innovative provider of pelletizing solutions. Its commitment to advanced technology, superior quality, customization, and exceptional customer service sets it apart as a leader in the market. As the company continues to expand its range of pelletizers and enhance its capabilities, it is poised to meet the evolving needs of its customers and remain at the forefront of the pelletizing industry.In conclusion, {Company Name} is dedicated to delivering top-of-the-line pelletizing solutions that cater to the distinct requirements of its customers. With its advanced technology, superior quality, customization options, and comprehensive support and service, the company has established itself as a go-to provider for businesses seeking high-performing and reliable pelletizers. As the demand for pelletizing equipment continues to grow, {Company Name} is well-equipped to meet the needs of its customers and maintain its position as a leader in the industry.

High-Quality LDPE Extruder Machine: Everything You Need to Know

The global plastic packaging market is experiencing significant growth, driven by the demand for convenient and lightweight packaging solutions. In this context, the use of LDPE (Low-Density Polyethylene) has gained prominence as a versatile material for packaging. To meet the increasing demand for LDPE packaging, {Company Name} has introduced a state-of-the-art LDPE extruder machine that promises to revolutionize the production of LDPE packaging materials.{Company Name} is a leading manufacturer of plastic processing equipment, with a strong reputation for delivering high-quality and innovative solutions to the industry. The company has been at the forefront of technological advancements in the plastic processing sector, and the introduction of the new LDPE extruder machine is a testament to its commitment to driving innovation.The LDPE extruder machine is designed to offer superior performance and efficiency in the production of LDPE packaging materials. It is equipped with advanced features that enable precise control over the extrusion process, resulting in consistent and high-quality output. The machine is capable of processing a wide range of LDPE resins, allowing for flexibility in producing various types of packaging materials tailored to specific customer requirements.One of the key highlights of the LDPE extruder machine is its streamlined and user-friendly design, which enhances operational efficiency and minimizes downtime. The machine is equipped with intuitive controls and automation features that facilitate easy operation and maintenance, making it an ideal choice for manufacturers looking to optimize their production processes. Additionally, the machine is built with robust and durable components, ensuring reliability and longevity in its performance.With sustainability being a pressing concern in the packaging industry, {Company Name} has incorporated eco-friendly features into the LDPE extruder machine. The machine is designed to optimize energy efficiency and minimize waste generation, aligning with the growing focus on sustainable manufacturing practices. By investing in the new LDPE extruder machine, manufacturers can reduce their environmental impact while meeting the growing demand for LDPE packaging materials.The introduction of the LDPE extruder machine is poised to make a significant impact on the global plastic packaging market. With its cutting-edge technology and performance capabilities, the machine presents new opportunities for manufacturers to enhance their production capabilities and meet the evolving needs of the packaging industry. By leveraging the capabilities of the LDPE extruder machine, manufacturers can explore new avenues for product development and market expansion.{Company Name} is committed to providing comprehensive support and expertise to its customers in adopting the new LDPE extruder machine. The company's team of skilled engineers and technical specialists are readily available to assist customers in implementing the machine into their production facilities and optimizing its performance. Additionally, {Company Name} offers ongoing technical support and maintenance services to ensure the seamless operation of the LDPE extruder machine.In conclusion, the introduction of the new LDPE extruder machine by {Company Name} represents a significant advancement in the production of LDPE packaging materials. With its advanced technology, efficiency, and sustainability features, the machine is poised to reshape the landscape of the plastic packaging market. As manufacturers look to capitalize on the growing demand for LDPE packaging, the LDPE extruder machine offers a compelling solution to drive innovation and competitiveness in the industry. With the support of {Company Name}, manufacturers can unlock the full potential of the LDPE extruder machine and stay ahead in the dynamic and evolving packaging market.

Pulverizer Machine For Plastic: A Complete Guide

Plastic waste has become a significant environmental issue in recent years, causing harm to our planet and wildlife. As such, the demand for efficient plastic recycling solutions has never been greater. In response to this urgent need, a leading company in the industry has introduced a groundbreaking pulverizer machine for plastic. This state-of-the-art machine is designed to effectively and efficiently process plastic waste, turning it into raw material that can be used to manufacture new products.The pulverizer machine is equipped with advanced technology that enables it to handle various types of plastic waste, including bottles, containers, packaging materials, and more. This versatility makes it an ideal solution for recycling facilities and plastic manufacturers looking to reduce their environmental footprint.One of the key features of this pulverizer machine is its high-speed performance, which allows for quick and efficient processing of large volumes of plastic waste. This not only increases productivity but also helps to reduce energy consumption, making it a cost-effective and eco-friendly solution.Additionally, the machine is designed with user-friendly controls and safety features to ensure smooth operation and minimize the risk of accidents. This makes it suitable for use in a wide range of manufacturing and recycling facilities, regardless of their size or production capacity.Furthermore, the company behind this innovative pulverizer machine is known for its commitment to quality and customer satisfaction. With years of experience in the industry, they have developed a strong reputation for delivering reliable and high-performance machinery to their clients.In addition to offering top-notch products, the company also provides comprehensive support services, including installation, training, and maintenance. This ensures that their clients can maximize the benefits of their investment in the pulverizer machine and achieve their sustainability goals.Moreover, the company's commitment to sustainability extends beyond their products and services. They have implemented environmentally friendly practices within their own operations, such as reducing waste, conserving energy, and promoting recyclability. This demonstrates their dedication to making a positive impact on the environment and the communities they serve.The introduction of this advanced pulverizer machine for plastic marks a significant step forward in the ongoing battle against plastic waste. By providing a reliable and efficient solution for recycling plastic, the company is helping to create a more sustainable and circular economy.As the demand for plastic recycling continues to grow, it is crucial for companies to invest in innovative technologies that can help them meet their environmental targets. With its cutting-edge pulverizer machine, this leading company is well-positioned to support the transition towards a more sustainable future.In conclusion, the introduction of the pulverizer machine for plastic by this prominent company represents a major advancement in the field of plastic recycling. With its advanced technology, high-speed performance, and commitment to customer support, this machine is set to make a significant impact on the industry. As the world strives to address the plastic waste crisis, innovative solutions like this will play a crucial role in creating a more sustainable and environmentally friendly future.

Revolutionary Recycled Plastic Extruder: Boosting Sustainability Efforts in Manufacturing

Title: Cutting-edge Recycled Plastic Extruder revolutionizes plastic waste managementIntroduction:In an increasingly environmentally conscious world, finding innovative ways to tackle the rising problem of plastic waste has become a top priority. One company, with their groundbreaking Recycled Plastic Extruder, is leading the charge in plastic waste management, offering an effective solution for transforming plastic waste into valuable resources.Company Background:{Company Name} is a pioneering company that specializes in developing sustainable solutions for plastic waste reduction. With a passion for creating a cleaner and greener future, they have dedicated extensive research and development efforts to engineer an advanced Recycled Plastic Extruder.The Recycled Plastic Extruder:{Company Name} has designed a state-of-the-art Recycled Plastic Extruder, which utilizes cutting-edge technology to process plastic waste materials into useful products. This innovative machine represents a breakthrough in sustainable recycling methods, contributing to the circular economy while reducing the reliance on fossil fuels and minimizing environmental pollution.Key Features:1. High Efficiency: The Recycled Plastic Extruder boasts a high production capacity, enabling the processing of large volumes of plastic waste in a shorter time frame. This feature is critical for tackling the massive amount of plastic waste generated globally.2. Versatility: The machine is capable of converting various types of plastic waste, including PET bottles, HDPE containers, and PP packaging materials, into a range of reusable products. This versatility promotes a more comprehensive approach to plastic waste recycling.3. Energy-Efficient: Designed with energy conservation in mind, the extruder operates on low power consumption, greatly reducing the environmental impact during the recycling process. This efficiency ensures cost-effectiveness and sustainability.4. Customizable Output: The Recycled Plastic Extruder can be tailored to produce different forms of recycled plastic, such as plastic pellets, sheets, or even 3D printing filaments, based on specific industry requirements.Environmental Benefits:The implementation of {Company Name}'s Recycled Plastic Extruder can provide numerous environmental benefits, including:1. Waste Reduction: By recycling plastic waste, the extruder helps divert it from landfills and oceans, significantly reducing the overall environmental burden caused by plastic pollution.2. Resource Conservation: By turning plastic waste into valuable resources, the extruder conserves natural resources that would have otherwise been utilized in the production of virgin plastic.3. Carbon Footprint Reduction: The extruder lowers greenhouse gas emissions by minimizing the need for producing new plastics, as well as by reducing the energy requirements during the recycling process.Market Impact:{Company Name}'s Recycled Plastic Extruder has the potential to revolutionize plastic waste management and create substantial opportunities across various industries. The availability of recycled plastic materials will encourage businesses to adopt environmentally friendly practices and reduce their ecological footprint.Additionally, as global awareness of plastic waste intensifies, governments may implement stricter regulations demanding increased recycling rates. In such a scenario, the Recycled Plastic Extruder offers an efficient and sustainable solution for companies looking to comply with these regulations while minimizing costs.Future Prospects:{Company Name} is committed to continued research and development, aiming to enhance the functionality and efficiency of their Recycled Plastic Extruder even further. They envision expanding their market reach and collaborating with industry partners to optimize plastic waste management systems globally.Conclusion:With their innovative Recycled Plastic Extruder, {Company Name} is at the forefront of plastic waste management, offering a sustainable and efficient solution to transform plastic waste into valuable resources. By actively pushing for a circular economy and promoting environmentally responsible practices, they are paving the way towards a cleaner and greener future.

Innovative Plastic Recycling Machine Plant Promises Sustainable Solution for Plastic Waste

Plastic pollution is a growing concern for the environment, with millions of tonnes of plastic waste ending up in our landfills and oceans every year. In response to this environmental crisis, the company, a leading provider of innovative solutions for the recycling industry, has recently unveiled a state-of-the-art plastic recycling machine plant that is set to revolutionize the way plastic waste is processed and reused.The new plant is a significant milestone for the company, as it represents a major investment in sustainable technology and underscores their commitment to creating a circular economy for plastics. The plant is equipped with cutting-edge technology that is capable of processing a wide variety of plastic waste, including bottles, packaging, and other single-use plastics, and turning them into high-quality recycled pellets that can be used to make new plastic products.One of the key features of the plant is its advanced sorting and cleaning system, which is able to efficiently separate different types of plastics and remove any contaminants, such as labels, caps, and other non-plastic materials. This ensures that the recycled pellets produced by the plant are of the highest quality and can be used in a wide range of applications, from the production of new packaging materials to the manufacturing of durable plastic products.The new plant also incorporates innovative technology for the recycling of plastic films and flexible packaging, which are notoriously difficult to recycle due to their thin and flexible nature. With the introduction of this new plant, the company aims to address this challenge and significantly increase the recycling rate of these commonly used plastic materials.In addition to its advanced recycling capabilities, the plant is also designed with sustainability in mind. It is equipped with energy-efficient machinery and utilizes processes that minimize water consumption and waste generation. Furthermore, the plant is operated by a team of highly skilled professionals who are trained in the latest best practices for sustainable and environmentally friendly recycling.The introduction of this plastic recycling machine plant is expected to have a positive impact on the environment by reducing the amount of plastic waste that ends up in landfills and oceans. By providing a reliable and efficient solution for recycling plastic waste, the company is contributing to the global effort to combat plastic pollution and create a more sustainable future for the planet.Furthermore, the plant is also expected to create new opportunities for the local community by generating jobs and stimulating economic growth. As the demand for recycled plastics continues to grow, the plant is poised to play a crucial role in meeting this demand and supporting the development of a thriving recycling industry.The company's commitment to sustainability and innovation is further underscored by their ongoing research and development efforts to further improve the efficiency and capabilities of their recycling technology. They are continuously exploring new ways to recycle even more types of plastic waste and are dedicated to staying at the forefront of technological advancements in the recycling industry.With the unveiling of the new plastic recycling machine plant, the company is setting a new standard for sustainable plastic waste management and demonstrating their dedication to making a positive impact on the environment. By investing in cutting-edge recycling technology and embracing a circular economy approach, they are paving the way for a more sustainable and responsible handling of plastic waste. It is clear that their efforts are not only benefiting the environment but also contributing to the creation of a more sustainable future for generations to come.